Monitoring the connected car

Elastic ensures vehicle software is running smoothly before release to market by 24/7 engine-control unit monitoring of the new Land Rover Defender.

Improved reliability

Product Lifecycle Management data is accessible and digestible for tens of thousands of engineers and JLR management; Elastic provides accurate, complete, and instant alerting to ensure the platform is operational and available.

Optimized manufacturing operations

JLR management is able to check that the systems and tooling within manufacturing plants are performant, reducing waste, and minimizing vehicle production delays.

Powering the luxury experience of JLR connected vehicles

From multiple wins at Le Mans to a starring role in the latest James Bond movie, Jaguar Land Rover is one of the most iconic brands in the history of motoring. World renowned for automobiles that define "modern luxury" with the unique combination of beauty, speed, ruggedness, and innovation, Jaguar Land Rover started producing cars in the 1930s. Its most famous models include the celebrated E-type Jaguar sports car launched in 1961, and the Land Rover four-wheel drive vehicle that first rolled off the production line in 1948. Now in its ninth decade, Jaguar Land Rover counts among its customers Her Majesty The Queen of the United Kingdom, wartime Prime Minister Winston Churchill, and, more recently, celebrities including Daniel Craig and Reese Witherspoon.

Today's Jaguar Land Rover vehicles are some of the most advanced on and off the road thanks to the expertise of the company's Design, Engineering, and IT teams. These teams include Simon Ansell, Senior Director of Design, Engineering and Quality IT at Jaguar Land Rover, who is helping to keep the brand in pole position as it addresses the challenges facing the modern automobile industry.

Ansell's team plays a key role in efforts to reduce carbon emissions and increase safety, while delivering the thrilling driving experience the brand is known for. "We're now operating in a world where the technology aspects of the car are becoming more important than the pure mechanical engineering of the vehicle," he says.

Technology, at the heart of on- and off-road driving adventures

The latest Jaguar Land Rover products are connected to the cloud, via Wi-Fi or 4G so that owners always benefit from the most up-to-date entertainment and driving features, downloaded in real time. drivers also benefit from performance monitoring and can interact with their vehicle from anywhere in the world using a smartphone app. The automated production lines at Jaguar Land Rover are also packed with technology, from the hundreds of robots that assemble vehicles to the software that enables precision engineering with little or no human intervention.

It's a hugely complex process requiring careful monitoring at every step, including the performance of every component of the assembled vehicle, as well as the production line itself. The same level of detail is applied when designing and developing new vehicles. Known as Product Lifecycle Management (PLM), these processes help Jaguar Land Rover bring new, highly advanced cars to market quickly, while ensuring the design and manufacturing quality customers expect.

Data, the fuel that powers innovation and reliability

To power its PLM system, Jaguar Land Rover has deployed a Product Lifecycle Management Application tool suite, which is managed through a cluster of servers and is used by more than 10,000 engineers at the company. With so much information and so many end users — the team at Jaguar Land Rover set out to find a platform that supported the integration and analysis of massive volumes of data. Other important criteria included the ability to generate alerts automatically when data anomalies were detected, and that the platform APIs supported integration with partner systems.

Andy Walker, Senior Project Manager at Jaguar Land Rover, says, "One key thread in the performance of our vehicles and production lines is the quality of the data that is available to our leadership teams and engineers. There's a lot of it, and it needs to be accurate, complete, and available in an instant."

With the deployment of Elasticsearch, Jaguar Land Rover has taken an important step forward in monitoring its product lifecycle management. Elasticsearch pulls data automatically from many of the systems for detailed monitoring using machine learning and alerting that reports by exception on the production or vehicle testing process. "Our leadership teams and engineers are extremely busy, so it really reduces pressure when they only have to act on exceptions while allowing the technology to handle the rest. We have a fantastic setup with Elastic that allows us to do exactly that," says Walker.

Delivering high-quality software for the connected car 24/7

A specific area of PLM where Elastic is delivering crucial support is the monitoring of test rigs that put each new vehicle through its paces during development, especially the electronic and computing components. This includes a significant number of onboard electronic control units (ECUs) that run the software for everything from engine performance, wireless connectivity to the infotainment system.

These ‘hardware in the loop (HIL) rigs' run 24/7 at multiple Jaguar Land Rover plants around the world. The HIL rig simulates the software running in the ECUs and is connected to the sensors and the actuators in the vehicle. Elastic Stack monitors the HIL rigs unobtrusively for errors and predictive failures through one simple reporting by exception Kibana dashboard with 24/7 push alerts through Slack to mobile devices, meaning the test managers get more reliable and efficient tests and avoid extensive testing downtime.

The new Land Rover Defender includes significantly more technology than its predecessor and we had a very short timeline to get to market. Elastic helped ensure that the rigs were running, the results were getting uploaded, and that the software was running perfectly in the vehicle.

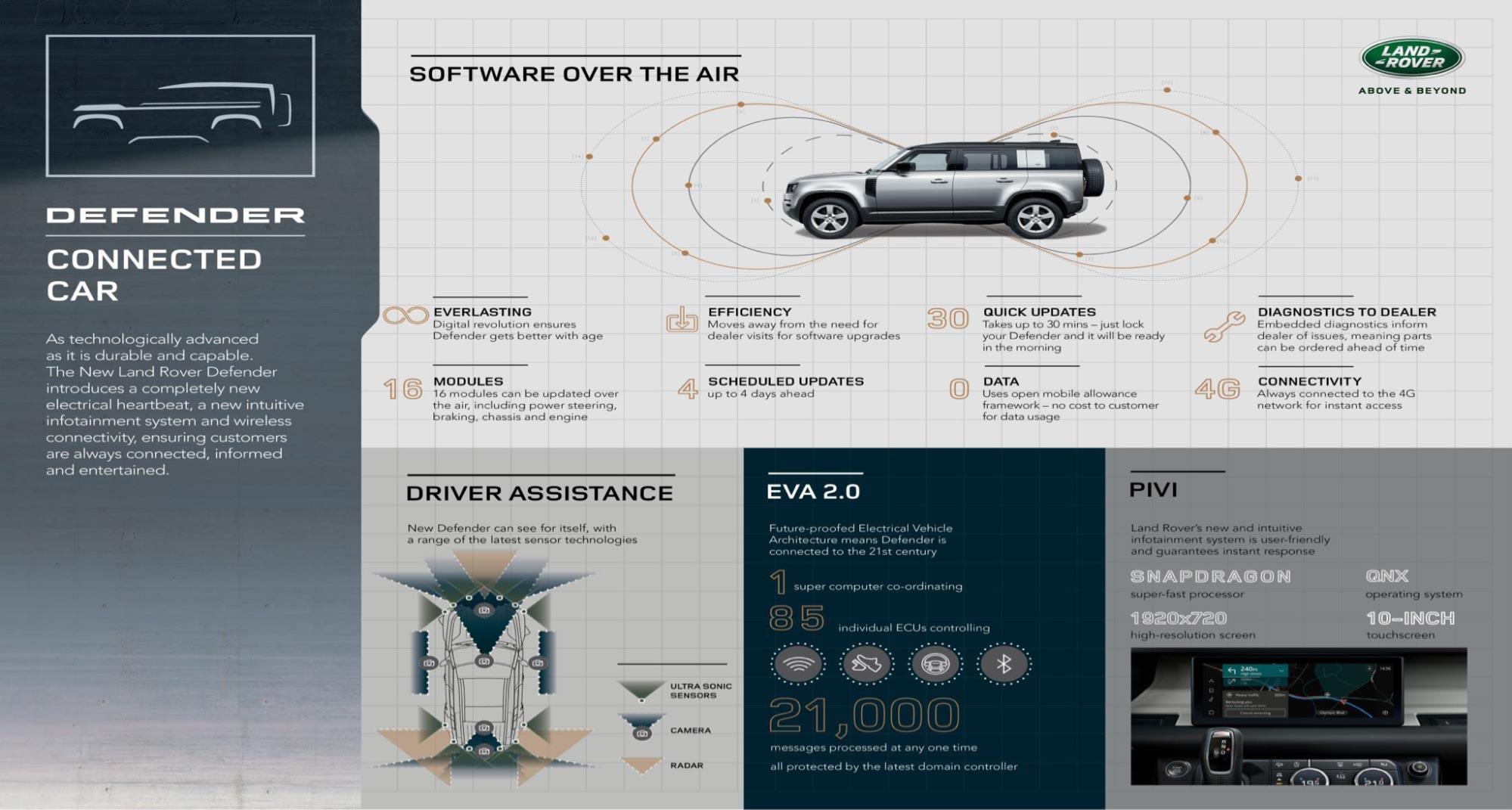

Elastic monitored data from vehicle technology testing rigs during the development of the new Land Rover Defender to ensure that the Defender's highly advanced connected features, as illustrated in this image, were correctly functioning and ready to go to market.

Getting more out of assets, delivering more to drivers

Ansell sees enormous potential for Elastic in two other areas at Jaguar Land Rover. The first is being able to report on the efficiency and utilization of manufacturing and technology assets, including licensed tools worth hundreds of millions of dollars, infrastructure including data storage, and manufacturing equipment. "We make a substantial investment in the technology that runs our organization. Understanding and maximizing the return on these assets is fundamental to the way that we report to the highest levels of the business. It gives us credibility and influence across the business" he says.

Elasticsearch can also be applied to the exchanges of data between Jaguar Land Rover and its suppliers, these transactions are increasing everyday, from anywhere in the world as global collaboration to drive innovation accelerates.

Elasticsearch gives us the ability to spot all the transactions between our suppliers and our JLR plants, ensuring that transactions are synchronized, and data quality is maintained. By optimizing the data transmissions, we can help engineering become more efficient and further optimize our supply chain.

Together, these enhancements contribute towards Jaguar Land Rover's overall competitiveness and brand reputation by accelerating innovation, driving down costs, and eliminating production errors.

Spot exceptions and maximize efficiency in the production line

Another tool that helps Jaguar Land Rover perform more efficiently is the Kibana visualization dashboard that runs on top of the content indexed by Elasticsearch. The company has introduced Kibana into one of its plant lines to monitor the vehicle production track that runs through the factory and plans to roll it out across the rest of the manufacturing plants to provide an at-a-glance view of the tracks in those locations as well.

Jaguar Land Rover is also connecting Kibana with its Advanced Product Quality Planning (APQP) process, which is used to support product development, especially in the automotive industry. "We can connect Kibana to the back end of our product lifecycle management systems to better understand the maturity of components and assemblies so that we can optimize and add efficiencies to the design lifecycle, as well," says Walker. As the company aims to meet the challenging auto industry goal of electrification before the end of the decade as well as to become a net carbon-zero business by 2039, this will help accelerate the launch of new models while supporting the consolidation of vehicle platforms and models produced in the next few years.

The ability to monitor the wider behavior of applications running in the Jaguar Land Rover business is another advantage of Elastic called out by Ansell. "Elastic Observability gives people the opportunity to detect and fix root cause events quickly. Critically, it can also be used easily by different business units with minimal IT or developer support. We don't need to send in a team of developers, which reduces strain on Jaguar Land Rover resources," he says.